Autogas filling skids

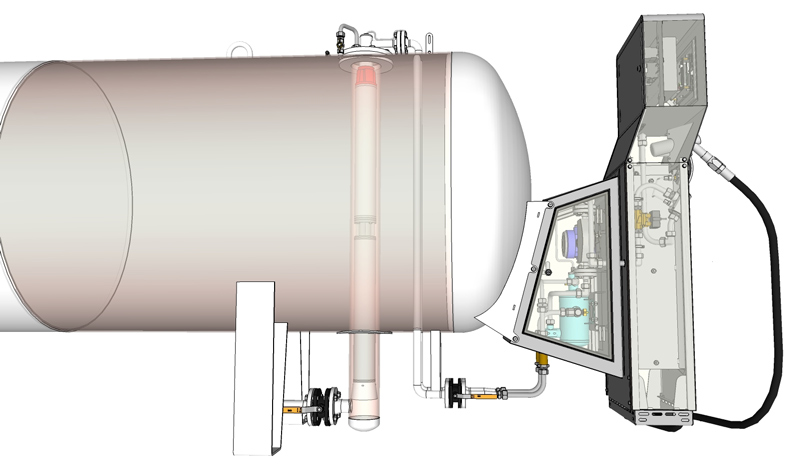

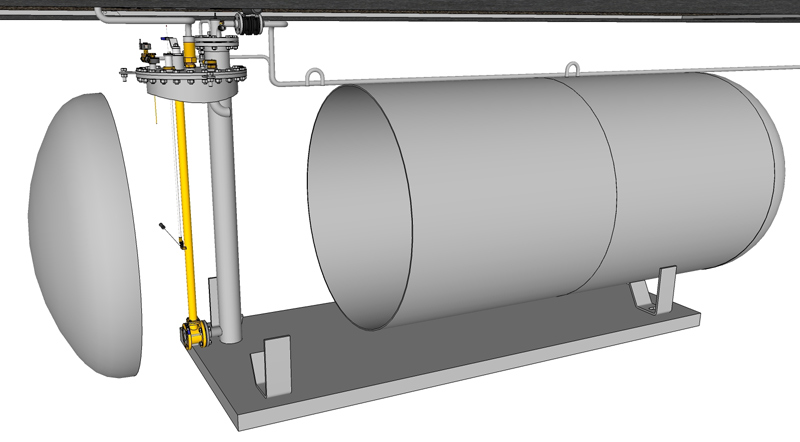

Compact autogas filling module is an elegant and economic solution, where the dispenser and the pump are fixed directly on the storage tank, therefore there is no need of supporting frame. Red Jacket submersible pump is placed in protective shaft directly in the tank. Autogas filling module is available in overground or underground version. Standard compact filling modules are offered with tanks of Ø1250 mm (2700l to 10000l); Ø1600mm and Ø2000mm – on demand.

Components of the filling module

- Red Jacket submersible pump type Premier LPG300V17-21 (or other types of RJ pumps) placed in a shaft, with inner bypass, with pump protection Differpress11 against the dry running.

- LPG dispenser KADATEC Corio or Corioduo, with a mass flow meter LPGmass (dispensing accuracy ±0.2%), or optionally dispenser ADAST.

- LPG monitoring system, informing about gas level in the tank.

Measurement of LPG is proceed by the mass flow meter with its own temperature compensation, dispensing accuracy of 0.2% and accurate information on gas density and gas composition. The module is supplied mounted; the only installation requirements are concrete panel and electric connection. The use of compact LPG fillings stations is ideal e.g. for easy complementation of autogas filling technology to the existing fuel stations.

Specifications of autogas filling module for Ø1250mm tank

| Volume | 4850 l | 6400 l | 9100 l | 10000 l |

|---|---|---|---|---|

| Max. weight | 2145 kg | 2830 kg | 4020 kg | 4420 kg |

| Max. tank filling | 85 % | |||

| Operating pressure | 1,56 MPa | |||

| Max. differential pressure | 0,92 MPa | |||

| Max.-min. flow rate | 50 l/min - 5 l/min | |||

| Dispensing accuracy | ±0,2 % | |||

| Operating temperature | -20/+40 °C | |||

| Electrical connection | 3x230/400V AC±15%, 50 Hz / 2,2 kW | |||

| Installation | Concrete plate according to the module dimensions | |||

| Dimensions (length x height x width) in mm | 4960 x 1250 x 1865 | 6220 x 1250 x 1865 | 8490 x 1250 x 1865 | 9460 x 1250 x 1865 |

| Certificates | European Directive 97/23/EC, CE 1017 CE certificate FTZU 12 ATEX 0080X, Ex II 2G IIA T3 |

|||